TMS at a Glance

Established in the year 2010, TMS Group specialises in manufacturing and catering the exact requirements of automobile industry with high quality electroplated components for 2 wheeler, 3 wheeler, cars,tractors and also railway signalling relays.

With this we have also expaned our footprints into electrical supplies for different industrial applications.

At TMS, We have best in class machinery & equipments with spacious work environment, great computer aided technology & experienced team of engineers & technicians to cater the growing demand for innovative auto-components.

The mangament of TMS Group is committed towards folllowing the best practises & to maintain high level of business ethics in its dealing with customers, suppliers, Govt & society.

Our quality management systems are certified for ISO 9001:2015

VISION

To globalise our product and continuously work towards excellence for customer satifaction in evey means.

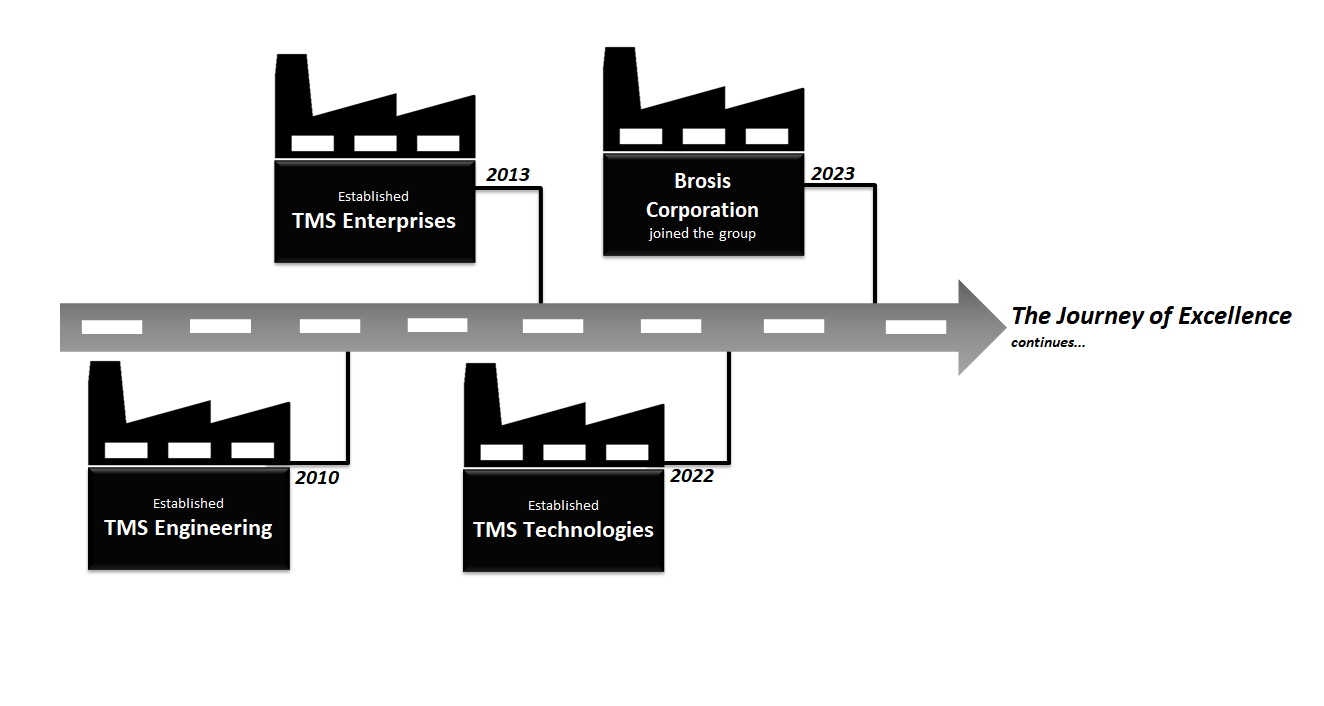

Milestones

Infrastructure

Plant Area

Owned Area - 7500 sq.ft

Working Area - 14000 sq.ft

Machinery

Press & Welding

| Mechanical power press machine | Specification | No’s |

| A mechanical power press shears, punches, forms, or assembles metal or other materials by means of tools or dies attached to slides or rams. | 10 Ton 20 Ton 30 Ton 50 Ton 75 Ton |

3 3 4 5 1 |

| Shearing Machine | Specification | No’s |

| Shearing machines are multipurpose devices used in the cutting of alloys and other sheet metal. | Hydraulic Shearing Machine | 1 |

| Lathe Machine | Specification | No’s |

| A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning | 4 feet | 1 |

| Buffing Machine | Specification | No’s |

| Flat Surface Polishing Machine can perform any polishing & deburring operation on any flat surface like Square/ Rectangular Tube, Solid Flat, Sheet Metal Component. | Single + double stationed 45mm | 2 |

| Milling Machine | Specification | No’s |

| A milling machine removes material from a work piece by rotating a cutting tool (cutter) and moving it into the work piece. | 5mm | 1 |

| Tapping Machine | Specification | No’s |

| Pneumatic threading machine or pneumatic threading arm is ideal if you often do threading. The thread tapping machine is also known under the name of “air tapping machine“. | M6 | 2 |

| Drill Machine | Specification | No’s |

| Drilling machines use a drilling tool that has cutting edges at its point. | 12mm /18mm /25mm | 5 |

| Spot Welding | Specification | No’s |

| Spot Welding machines use a method called resistance spot welding to join overlapping metals between two electrodes using electrical resistance. | 50 KVA 75KVA |

2 3 |

| Water cooling tower | Specification | No’s |

| Fiberglass reinforced plastic cooling tower for heat exchange allowing air and water to come into contact with each other to the lower temperature of hot water. | 1 |

Other machines as Cutting machine, Gas cutting machine, Hand press Machine, Belt Grinder, Bench grinders & Surface grinders. Also we have CO2 Welding machine & Arc welding machine & Air compressor.

In Total we have 55 machines & equipments utilised in manufacturing of auto components

Plating

| Plating Barrell | Specification | No’s |

| Barrel plating is a form of electroplating used for plating a high volume of smaller metal objects in one sitting | Azid Zinc Alkaline Zinc |

3 4 |

| Hot Air Drum Dryer | No’s |

| This operation helps remove the bulk of water and the hot air evaporates the remaining thin film to give a completely dry component. | 2 |

| Rectifiers | No’s |

| Rectifiers with digital controls regulate amperage and voltage more precisely. They allow the current to be “ramped up” as the parts enter plating or anodizing tanks, and turned off at precisely the right times | 3 |

| Effluent Treatment Plant | No’s |

| (ETP) are used for the removal of high amounts of organic compounds, debris, dirt, grit, pollution, toxic, non-toxic materials and polymers etc. from industrial effluent. | 3 |

| Scrubber Machine Setup | No’s |

| Scrubber systems are a diverse group of air pollution control devices that can be used to remove some particulates and gases from industrial exhaust streams. | 1 |